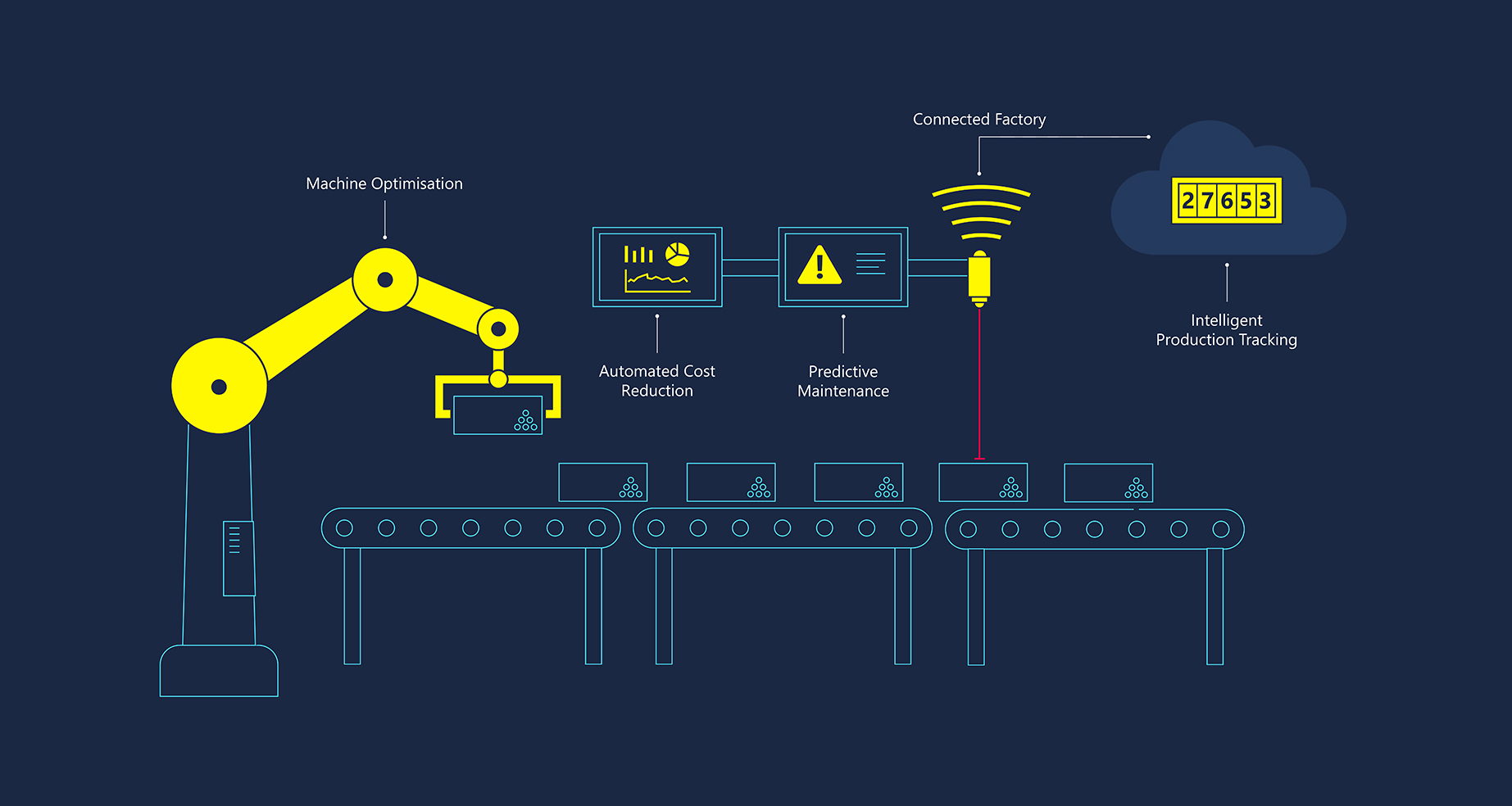

Factory of the Future. Powered by Microsoft Azure.

Real-Time Machine Optimisation

Telemetry relating to the performance of machines is collected in real-time and sent to Microsoft Azure. Machines can then be adjusted live, as the machine is running to ensure optimum performance and overall product quality.

Automated Cost Reduction

Data from toner cartridges is collected from the machine automation, and Microsoft Azure machine learning is used to predict when machines should stop filling. This results in savings of £240k per year on toner overspill.

Predictive Maintenance

Predictive maintenance using Microsoft Azure AI improves operational and cost efficiency by up to 10%. AI can predict when a machine is likely to fail and repairs are scheduled automatically to minimise downtime.

Connected Factory

Data from across the factory, including machine automation, human resource and financial data, is analysed to determine cost of labour, cost of production and what measures should be put in place for the factory to remain competitive.

Intelligent Production Tracking

Ricoh camera technology feeds into Microsoft Azure to track inventory at all stages of the production cycle. This commercialised solution enables Ricoh to inform its customers of the best way to set out their printing production areas.

"Microsoft Azure is a great platform to be able to deliver our factory of the future. We believe other frontline manufacturers would benefit greatly from Microsoft's expertise in this area."

Richard Aston, Digital Operations Engineering Manager, Ricoh